The crankshaft is a vital component in internal combustion engines, transforming the linear motion of pistons into rotational motion that powers vehicles and machinery. Its design and functionality are critical in determining the efficiency, performance, and reliability of an engine. The crankshaft's role is not merely mechanical; it embodies the intricate relationship between various engine parts, working harmoniously to deliver power while minimizing vibrations and wear. Understanding the crankshaft's intricacies opens a window into the elaborate world of engine mechanics, providing insights into its significance in modern engineering.

The history of the crankshaft dates back centuries, evolving from primitive designs to the highly engineered components we see in contemporary engines. Its development has paralleled advancements in materials and manufacturing techniques, allowing for stronger, lighter, and more efficient designs. Today, the crankshaft is crafted from high-strength steel or cast iron, designed to withstand immense stresses while operating at high speeds. This transformation reflects not only the technological evolution of automotive engineering but also the necessity for reliability in every aspect of vehicle performance.

As we delve deeper into the workings of the crankshaft, we will explore its various types, functions, and the maintenance practices that ensure longevity. From understanding the components involved in its operation to learning how it influences the overall engine performance, this article aims to provide a comprehensive overview of the crankshaft and its pivotal role in engine dynamics.

What is a Crankshaft and How Does it Work?

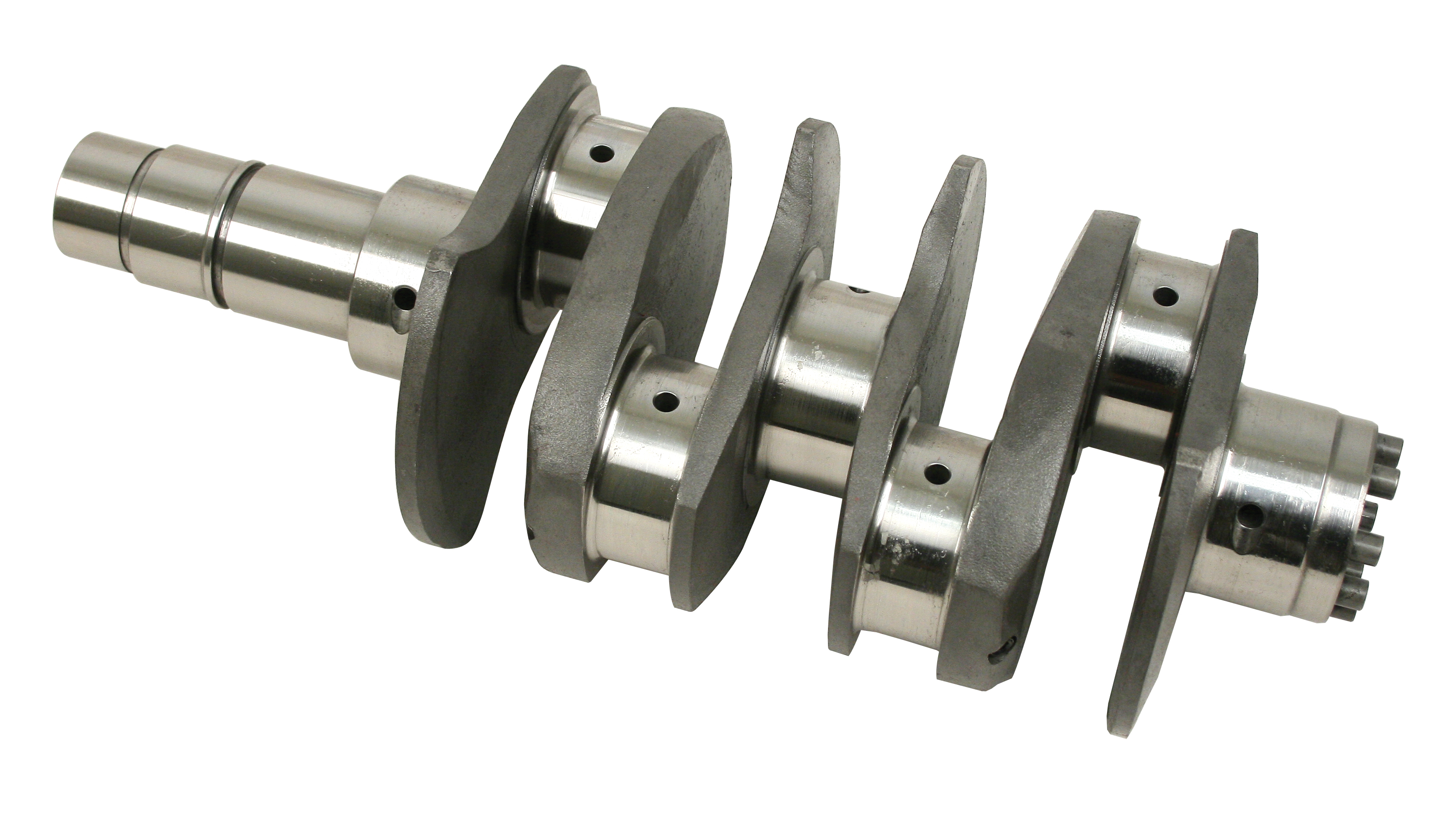

The crankshaft is a mechanical shaft that converts the linear motion of pistons into rotational motion. It is a core part of the engine, connecting to the pistons via connecting rods. As the pistons move up and down due to combustion, the crankshaft rotates, which in turn powers the vehicle's wheels.

What are the Main Components of a Crankshaft?

A crankshaft consists of several key components that work together to perform its function:

- Crankpins: These are the points where the connecting rods attach to the crankshaft.

- Main Journals: These are sections of the crankshaft that rest in the engine block's bearings.

- Counterweights: Designed to balance the crankshaft's weight and minimize vibrations.

- Flywheel: Attached to the end of the crankshaft, it helps smooth out the engine's power delivery.

How is a Crankshaft Designed?

The design of a crankshaft is critical to its performance. Engineers must consider various factors, including:

- Material Selection: High-strength materials are chosen to withstand the severe stresses of operation.

- Weight and Balance: A well-balanced crankshaft reduces vibrations and enhances engine performance.

- Manufacturing Processes: Techniques like forging or casting are used to create durable crankshafts.

Why is the Crankshaft Important in Engine Performance?

The crankshaft plays a crucial role in the overall performance of an engine. Its efficiency directly affects the power output and fuel economy of the vehicle. A well-designed crankshaft allows for smooth operation, reducing the risk of engine failure and ensuring longevity.

What Are the Common Problems Associated with Crankshafts?

Despite their robust design, crankshafts can encounter issues over time. Some common problems include:

- Crankshaft Wear: Over time, the bearings can wear, leading to increased friction and potential failure.

- Misalignment: If the crankshaft is not properly aligned, it can lead to increased wear and tear.

- Cracks and Breaks: High-stress conditions can cause the crankshaft to crack or break, necessitating immediate replacement.

How Can You Maintain a Crankshaft?

Proper maintenance is essential for prolonging the life of the crankshaft. Follow these tips for optimal care:

- Regular Oil Changes: Ensure the engine is properly lubricated to reduce friction.

- Check for Vibration: Unusual vibrations can indicate issues with the crankshaft or related components.

- Inspect Bearings: Regularly inspect and replace worn bearings to prevent further damage.

What Are the Different Types of Crankshafts?

There are several types of crankshafts, each designed for specific applications:

- Flat Crankshaft: Common in two-stroke engines and some V8 engines.

- Cross Plane Crankshaft: Often used in V8 engines to provide smoother operation.

- Inline Crankshaft: Found in inline engines, supporting simpler designs.

How Does a Crankshaft Affect Fuel Efficiency?

The design and efficiency of a crankshaft significantly impact fuel consumption. A well-balanced, lightweight crankshaft reduces the engine's workload, resulting in better fuel efficiency. Additionally, advancements in crankshaft technology, such as the use of lightweight materials and optimized designs, contribute to enhanced fuel economy across various vehicle types.

What Innovations Are Emerging in Crankshaft Technology?

As automotive technology continues to evolve, several innovations in crankshaft design and materials are emerging:

- Composite Materials: The use of lighter materials can reduce weight while maintaining strength.

- 3D Printing: This technology allows for more complex designs and reduced production times.

- Smart Sensors: Integrating sensors into crankshafts can provide real-time data on performance and wear.

In conclusion, the crankshaft is a fundamental element of engine mechanics, serving as the backbone of power generation in various vehicle types. By understanding its design, function, and maintenance, we can appreciate the complexity and importance of this component in automotive engineering. Whether in everyday vehicles or high-performance machines, the crankshaft remains a crucial player in the pursuit of efficiency and power on the road.